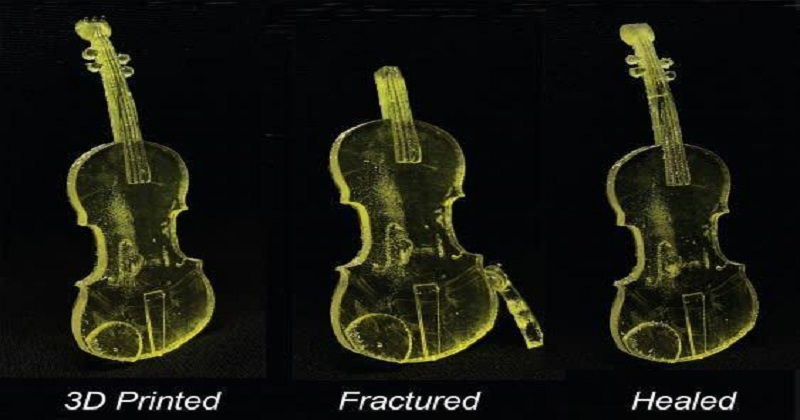

UNSW engineers have demonstrated a novel approach that allows 3D printed plastic to mend itself at ambient temperature using just light. The addition of special powder to the liquid resin during the printing process might subsequently help with easy and rapid repair in case of breakage of the material.

Professor Cyrille Boyer and his UNSW School of Chemical Engineering colleagues, Dr Nathaniel Corrigan and Mr Michael Zhang, have shown this. This is readily accomplished by shining regular LED lights on the printed plastic for approximately an hour, which causes a chemical reaction and the merging of the two shattered parts.

When this procedure is completed, the mended plastic becomes much stronger than it was before it got damaged. Chemical waste can be decreased in the future if the process is further developed and commercialised.

Also Read: World’s longest flexible fibre battery made by MIT engineers

The findings have been published in the journal Angewandte Chemie International Edition. The powdered additive utilised by the researchers was a trithiocarbonate, also known as a reversible addition-fragmentation chain transfer (RAFT) agent. The RAFT agent aids in the reordering of the material’s nanoscopic network of atoms and allows the fractured parts to be united.

Post Your Comments